Local minerals.

Global needs.

Every day, people all over the world use the metals we’ll mine. Copper for electric piping, cobalt in smart phone batteries, nickel in cars and aircraft, palladium and platinum in medical and dental instruments. And every day, the need is growing.

We will need to mine as much copper over the next 25 years as we mined in the past 5,000 years.6

The amount of nickel used per car could go from 20 kg to 40-50 kg by 2025,2 more than doubling the need.

Annual global cobalt consumption is expected to reach 220,000 tons in 2025, increasing to 390,000 tons in 2030.3 That’s almost double.

While recycling is important, the global demand for these metals exceeds what recycling can provide.

Green energy requires metals, too.

The world is demanding greener energy, which in turn demands the metals we mine. One wind turbine contains 4.7 tons of copper — the weight of over two cars. Solar panels require copper and nickel. Electric cars use cobalt and nickel. The only way to acquire these metals: mining.

World-class technology for a world-class project.

At Twin Metals Minnesota, we’re using best-in-class technology to design, build and operate a modern underground mine that prioritizes safety for both our workers and the environment. See what a difference modern mining can be.

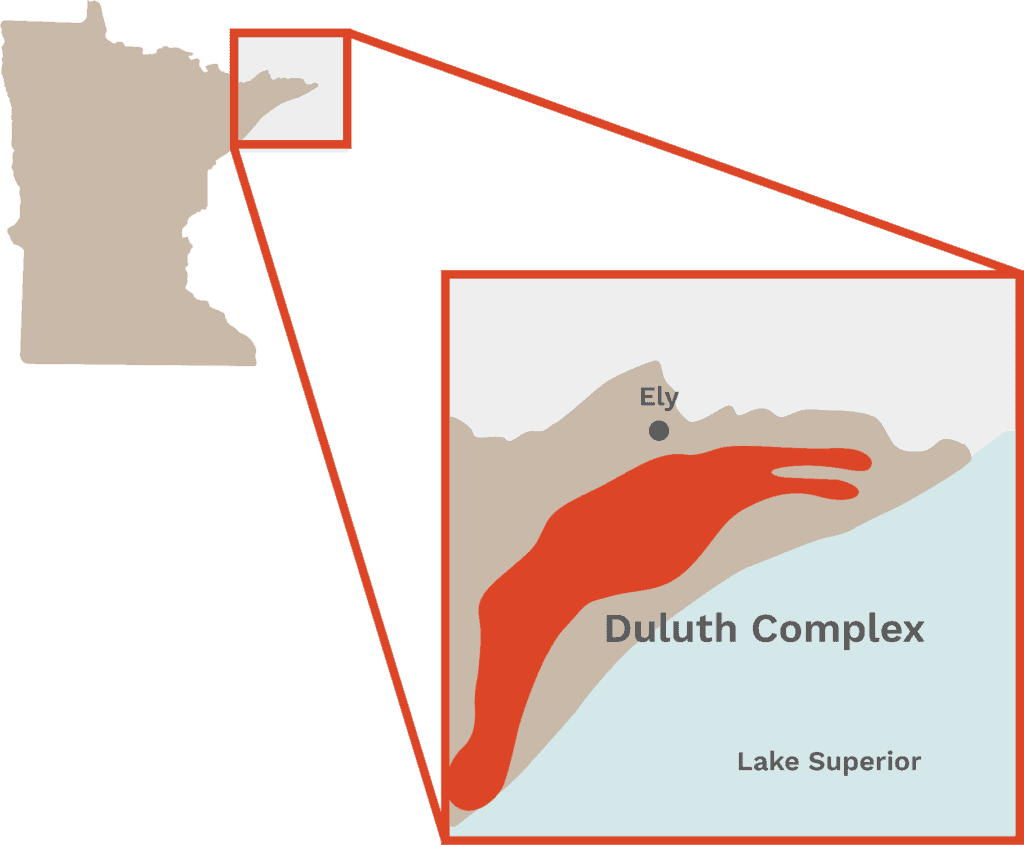

The country needs Minnesota.

Many of the metals the U.S. needs are found in Minnesota.

The Twin Metals project targets minerals in one area of the Duluth Complex called the Maturi Deposit. We’ve studied this deposit for more than a decade.

1 Source : Reportlinker

2 Source : Reuters

3 Source : JRC Science for Policy Report

4 Source : Mining Minnesota

5 Source : Twin Metals

6 Source : World Bank